Butyraldehyde

| |

| |

| |

| Names | |

|---|---|

| IUPAC name

Butyraldehyde | |

| Systematic IUPAC name

Butanal | |

| Identifiers | |

3D model (JSmol) |

|

| 3DMet | |

| ChEBI | |

| ChEMBL | |

| ChemSpider | |

| ECHA InfoCard | 100.004.225 |

| EC Number |

|

| KEGG | |

PubChem CID |

|

| RTECS number |

|

| UNII | |

| UN number | 1129 |

CompTox Dashboard (EPA) |

|

| |

| |

| Properties | |

| C4H8O | |

| Molar mass | 72.11 g/mol |

| Appearance | colorless liquid |

| Odor | pungent, aldehyde odor |

| Density | 0.8016 g/mL |

| Melting point | −96.86 °C (−142.35 °F; 176.29 K) |

| Boiling point | 74.8 °C (166.6 °F; 347.9 K) |

| 7.6 g/100 mL (20 °C) | |

| Solubility | miscible with organic solvents |

| log P | 0.88 |

| −46,08·10−6 cm3/mol | |

Refractive index (nD) |

1.3766 |

| Viscosity | 0.45 cP (20 °C) |

| 2.72 D | |

| Thermochemistry | |

Std enthalpy of combustion (ΔcH⦵298) |

2470.34 kJ/mol |

| Hazards | |

| Safety data sheet | Sigma-Aldrich |

| GHS pictograms |   [2] [2] |

| GHS Signal word | Danger |

| H225, H319[2] | |

| P280, P304+340, P302+352, P210, P305+351+338[2] | |

| NFPA 704 (fire diamond) | |

| Flash point | −7 °C (19 °F; 266 K) |

| 230 °C (446 °F; 503 K) | |

| Explosive limits | 1.9–12.5% |

| Lethal dose or concentration (LD, LC): | |

LD50 (median dose) |

2490 mg/kg (rat, oral) |

| Related compounds | |

Related aldehyde |

Propionaldehyde Pentanal |

Related compounds |

Butan-1-ol Butyric acid, isobutyraldehyde |

Except where otherwise noted, data are given for materials in their standard state (at 25 °C [77 °F], 100 kPa). | |

| Infobox references | |

Butyraldehyde

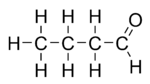

Butyraldehyde, also known as butanal, is an organic compound with the formula CH3(CH2)2CHO. This compound is the aldehyde derivative of butane. It is a colourless flammable liquid with an unpleasant smell. It is miscible with most organic solvents.

Production

Butyraldehyde is produced almost exclusively by the hydroformylation of propylene:

- CH3CH=CH2 + H2 + CO → CH3CH2CH2CHO

Traditionally, hydroformylation was catalyzed by cobalt carbonyl and later rhodium complexes of triphenylphosphine. The dominant technology involves the use of rhodium catalysts derived from the water-soluble ligand tppts. An aqueous solution of the rhodium catalyst converts the propylene to the aldehyde, which forms a lighter immiscible phase. About 6 billion kilograms are produced annually by hydroformylation. A significant application is its conversion to 2-ethylhexanol for production of plasticizers.

_phthalate.svg.png.webp)

Butyraldehyde can be produced by the catalytic dehydrogenation of n-butanol. At one time, it was produced industrially by the catalytic hydrogenation of crotonaldehyde, which is derived from acetaldehyde.[3]

Upon prolonged exposure to air, butyraldehyde oxidizes to form butyric acid.

References

- Merck Index, 11th Edition, 1591.

- Record of Butyraldehyde in the GESTIS Substance Database of the Institute for Occupational Safety and Health, accessed on 13 March 2020.

- Boy Cornils, Richard W. Fischer, Christian Kohlpaintner "Butanals" in Ullmann's Encyclopedia of Industrial Chemistry, 2000, Wiley-VCH, Weinheim. doi:10.1002/14356007.a04_447.