Tetraethoxymethane

Tetraethoxymethane is a chemical compound which is formally formed by complete ethylation of the hypothetical orthocarbonic acid C(OH)4 (orthocarboxylic acid violates the Erlenmeyer rule and is unstable in free state).

| |

| Names | |

|---|---|

| Other names

Tetraethyl orthocarbonate | |

| Identifiers | |

3D model (JSmol) |

|

| ChemSpider | |

| ECHA InfoCard | 100.000.985 |

| EC Number |

|

PubChem CID |

|

| UNII | |

CompTox Dashboard (EPA) |

|

| |

| |

| Properties | |

| C9H20O4 | |

| Molar mass | 192.25 g·mol−1 |

| Appearance | liquid |

| Density | 0.919 |

| Boiling point | 159.5 °C (319.1 °F; 432.6 K) |

| Hazards | |

| GHS pictograms |   |

| H226, H315, H319, H335 | |

Except where otherwise noted, data are given for materials in their standard state (at 25 °C [77 °F], 100 kPa). | |

| Infobox references | |

History

Tetraethoxymethane was described the first time in 1864.[1]

Synthesis

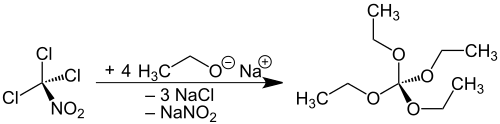

The preparation of tetraethoxymethane from the highly toxic trichloronitromethane is known in the literature[1][2][3][4] and achieves only yields of 46-49[3] to 58%:[4]

The obvious synthetic route from tetrachloromethane does not provide the desired product, as in the homologous tetramethoxymethane.[5]

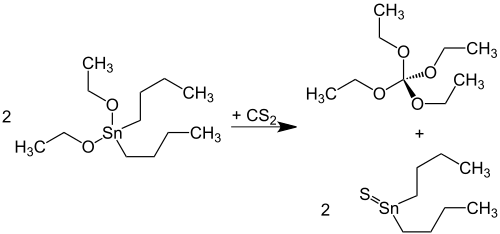

Starting from the less toxic trichloroacetonitrile (compared with trichloronitromethane), higher yields can be obtained (up to 85%).[6] An alternative reaction, bypassing problematic reactants, is the reaction of dialkyltin dialkoxides with carbon disulfide at elevated temperature in an autoclave:[7]

A more recent synthesis starts directly from sodium ethoxide, tin(IV)chloride, and carbon disulfide.[8]

Properties

Tetraethoxymethane is a water-clear, aromatic or fruity smelling,[9] liquid of low-viscosity which is unstable against strong acids and strong bases.[10]

Uses

Tetraethoxymethane can be used as a solvent and for the alkylation of CH-acidic compounds (e.g. phenols and carboxylic acids). In addition, it reacts with amines, enol ethers and sulfonamides,[11] whereby spiro compounds can also be obtained. Spiro orthocarbonates (SOCs)[12] are of some industrial interest, as they are used as additives for reducing shrinkage during the polymerization of epoxides (they are used as expanding monomers).[13]

References

- H. Bassett, Ueber das vierfach-basische kohlensaure Aethyl, Ann. 132, 54 (1864), doi:10.1002/jlac.18641320106.

- H. Tieckelmann, H.W. Post, The preparation of methyl, ethyl, propyl, and butyl orthocarbonates, J. Org. Chem., 13 (2), 265–267 (1948), doi:10.1021/jo01160a014.

- "Ethyl Orthocarbonate". Organic Syntheses. doi:10.15227/orgsyn.032.0068.

- Europäische Patentschrift EP 0881212 B1, Production method of aminobenzene compound, Erfinder: H. Hashimoto et al., Anmelder: Takeda Chemical Industries, Ltd., veröffentlicht am 30. Oktober 2001.

- R.H. De Wolfe, Carboxylic ortho acid derivatives: preparation and synthetic applications, Organic Chemistry, Vol. 14, Academic Press, Inc. New York – London, 1970, ISBN 978-0-12-214550-6.

- US-Patent US 6825385, Process for the preparation of orthocarbonates, Erfinder: G. Fries, J. Kirchhoff, Anmelder: Degussa AG, erteilt am 30. November 2004.

- S. Sakai et al., Reaction of Dialkyltin Dialkoxides with Carbon Disulfide at Higher Temperature. Preparation of Orthocarbonates, J. Org. Chem., 36 (9), 1176 (1971), doi:10.1021/jo00808a002.

- S. Sakai et al., A new method for preparation of tetraalkyl orthocarbonates from sodium alkoxides, tetrachlorostannane, and carbon disulfide, Synthesis 1984 (3), 233–234, doi:10.1055/s-1984-30785.

- J. H. Ruth, Odor Thresholds and Irritation Levels of Several Chemical Substances: A Review, Am. Ind. Hyg. Assoc. J. 47, A-142 – A-151, (1986).

- Sigma-Aldrich Co., product no. {{{id}}}.

- W. Kantlehner et al., Die präparative Chemie der O- und N-funktionellen Orthokohlensäure-Derivate, Synthesis, 1977, 73–90.

- D.T. Vodak et al., One-Step Synthesis and Structure of an Oligo(spiro-orthocarbonate), J. Am. Chem., Soc., 124, 4942–4943 (2002), doi:10.1021/ja17683i.

- R. Acosta Ortiz et al., Novel diol spiro orthocarbonates derived from glycerol as anti-shrinkage additives for the cationic photopolymerization of epoxy monomers, Polymer International, 59(5), 680–685 (2010), doi:10.1002/pi.2755.