Slip (materials science)

In materials science, slip is the large displacement of one part of a crystal relative to another part along crystallographic planes and directions.[1] Slip occurs by the passage of dislocations on close packed planes which are planes containing the greatest number of atoms per area and in close-packed directions (most atoms per length). Close-packed planes are known as slip or glide planes. A slip system describes the set of symmetrically identical slip planes and associated family of slip directions for which dislocation motion can easily occur and lead to plastic deformation. The magnitude and direction of slip are represented by the Burgers vector.

An external force makes parts of the crystal lattice glide along each other, changing the material's geometry. A critical resolved shear stress is required to initiate a slip.[2]

Slip systems

Face centered cubic crystals

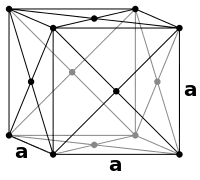

Slip in face centered cubic (fcc) crystals occurs along the close packed plane. Specifically, the slip plane is of type {111}, and the direction is of type <110>. In the diagram on the right, the specific plane and direction are (111) and [110], respectively.

Given the permutations of the slip plane types and direction types, fcc crystals have 12 slip systems.[3] In the fcc lattice, the norm of the Burgers vector, b, can be calculated using the following equation:[4]

Where a is the lattice constant of the unit cell.

Body centered cubic crystals

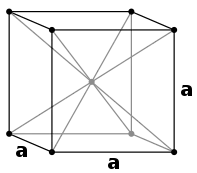

Slip in body-centered cubic (bcc) crystals occurs along the plane of shortest Burgers vector as well; however, unlike fcc, there are no truly close-packed planes in the bcc crystal structure. Thus, a slip system in bcc requires heat to activate.

Some bcc materials (e.g. α-Fe) can contain up to 48 slip systems. There are six slip planes of type {110}, each with two <111> directions (12 systems). There are 24 {123} and 12 {112} planes each with one <111> direction (36 systems, for a total of 48). Although the number of possible slip systems is much higher in bcc crystals than fcc crystals, the ductility is not necessarily higher due to increased lattice friction stresses.[3] While the {123} and {112} planes are not exactly identical in activation energy to {110}, they are so close in energy that for all intents and purposes they can be treated as identical. In the diagram on the right the specific slip plane and direction are (110) and [111], respectively.[4]

Hexagonal close packed crystals

Slip in hexagonal close packed (hcp) metals is much more limited than in bcc and fcc crystal structures. Usually, hcp crystal structures allow slip on the densely packed basal {0001} planes along the <1120> directions. The activation of other slip planes depends on various parameters, e.g. the c/a ratio. Since there are only 2 independent slip systems on the basal planes, for arbitrary plastic deformation additional slip or twin systems needs to be activated. This typically requires a much higher resolved shear stress and can result in the brittle behavior of some hcp polycrystals. However, other hcp materials such as pure titanium show large amounts of ductility.[5]

Cadmium, zinc, magnesium, titanium, and beryllium have a slip plane at {0001} and a slip direction of <1120>. This creates a total of three slip systems, depending on orientation. Other combinations are also possible.[6]

There are two types of dislocations in crystals that can induce slip - edge dislocations and screw dislocations. Edge dislocations have the direction of the Burgers vector perpendicular to the dislocation line, while screw dislocations have the direction of the Burgers vector parallel to the dislocation line. The type of dislocations generated largely depends on the direction of the applied stress, temperature, and other factors. Screw dislocations can easily cross slip from one plane to another if the other slip plane contains the direction of the Burgers vector.[2]

See also

References

- Jastrzebski, D. Nature and Properties of Engineering Materials (Wiley International ed.).

- , Hull D., Bacon, D.J (2001); "Introduction to Dislocations", 4th ed., ISBN 0-7506-4681-0

- Soboyejo, Wole O. (2003). "7.8 Crystal Structure and Dislocation Motion". Mechanical properties of engineered materials. Marcel Dekker. ISBN 0-8247-8900-8. OCLC 300921090.

- Van Vliet, Krystyn J. (2006); "3.032 Mechanical Behavior of Materials" Archived 2009-09-17 at the Wayback Machine

- Orozco-Caballero, Alberto; Li, Feng; Esqué-de los Ojos, Daniel; Atkinson, Michael D.; Quinta da Fonseca, João (2018). "On the ductility of alpha titanium: The effect of temperature and deformation mode". Acta Materialia. 149: 1–10. doi:10.1016/j.actamat.2018.02.022. ISSN 1359-6454.

- Callister, William D., Jr. (2007); "Materials Science and Engineering: An Introduction", ISBN 0-471-73696-1

External links

- An online tutorial on slip, explained on a promotional site for materials science at the University of Cambridge