Master cylinder

In automotive engineering, the master cylinder is a control device that converts force (commonly from a driver's foot) into hydraulic pressure. This device controls slave cylinders located at the other end of the hydraulic system.

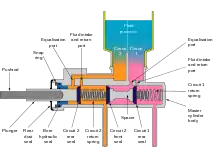

As piston(s) move along the bore of the master cylinder, this movement is transferred through the hydraulic fluid, to result in a movement of the slave cylinder(s). The hydraulic pressure created by moving a piston (inside the bore of the master cylinder) toward the slave cylinder(s) compresses the fluid evenly, but by varying the comparative surface area of the master cylinder and each slave cylinder, one can vary the amount of force and displacement applied to each slave cylinder, relative to the amount of force and displacement applied to the master cylinder.[1]

Vehicle applications

The most common vehicle uses of master cylinders are in brake and clutch systems. In brake systems, the operated devices are cylinders inside brake calipers and/or drum brakes; these cylinders may be called wheel cylinders or slave cylinders, and they push the brake pads towards a surface that rotates with the wheel (this surface is typically either a drum or a disc, a.k.a. a rotor) until the stationary brake pad(s) create friction against that rotating surface (typically the rotating surface is metal or ceramic/carbon, for their ability to withstand heat and friction without wearing-down rapidly). In the clutch system, the device which the master cylinder operates is called the slave cylinder; it moves the throw out bearing until the high-friction material on the transmission's clutch disengages from the engine's metal (or ceramic/carbon) flywheel. For hydraulic brakes or clutches alike, flexible high-pressure hoses or inflexible hard-walled metal tubing may be used; but the flexible variety of tubing is needed for at least a short length adjacent to each wheel, whenever the wheel can move relative to the car's chassis (this is the case on any car with steering and other suspension movements; some drag racers and go-karts have no rear suspension, as the rear axle is welded to the chassis, and some antique cars also have no rear suspension movement).[2]

A reservoir above each master cylinder supplies the master cylinder with enough brake fluid to avoid air from entering the master cylinder (even the typical clutch uses brake fluid, but it may also be referred to as "clutch fluid" in a clutch application). Each piston in a master cylinder operates a brake circuit, and for modern light trucks and passenger cars, usually, a brake circuit leads to a brake caliper or shoe on only two of the vehicle's wheels, and the other brake circuit provides brake pressure to slow down and stop the other two wheels. This is done in a diagonally split hydraulic system. If there is a hydraulic failure in the brake lines served by the master cylinder's secondary piston both pistons will move forward when the brakes are applied, but there is nothing to resist piston travel except the secondary piston spring. This lets the primary piston build up only a small amount of pressure until the secondary piston bottoms in the cylinder bore. Then the primary piston will build enough hydraulic pressure to operate the brakes served by this half of the system. In case of a hydraulic failure in the brake system served by the primary piston, the primary piston will move forward when the brakes are applied but will not build up hydraulic pressure. In this case, very little force is transferred to the secondary piston through the primary piston spring until the piston extension screw comes in contact with the secondary piston. Then, pushrod force is transmitted directly to the secondary piston and enough pressure is built up to operate its brakes.

With only 1 system working there are longer stopping distances and repairs should be done before driving again.[3][4][5][6]

See also

References

- "Chapter 7 : Basic Hydraulic System Theory" (PDF). Peterverdone.com. Retrieved 2018-07-06.

- "Viscosity of Automotive Brake Fluids". Anton Paar Wiki. Retrieved 2018-05-25.

- [pg 1549 ], Automotive Technology A systems approach (3rd Canadian edition). publisher (Nelson Education)

- yourmechanic.com, Symptoms of a Bad or Failing ABS Fluid Level Sensor

- nhtsa.gov, National Highway Traffic Safety Administration, DOT HS 811 251, April 2010, Human Performance Evaluation of Light Vehicle Brake Assist Systems, page 33

- 2017 CT.gov Commercial Vehicle Safety Alliance, Hydraulic Brake System and Trailer Brake Inspection Procedure, 2012

- How Master Cylinders and Combination Valves Work, How Stuff Works.