Herschel–Bulkley fluid

The Herschel–Bulkley fluid is a generalized model of a non-Newtonian fluid, in which the strain experienced by the fluid is related to the stress in a complicated, non-linear way. Three parameters characterize this relationship: the consistency k, the flow index n, and the yield shear stress . The consistency is a simple constant of proportionality, while the flow index measures the degree to which the fluid is shear-thinning or shear-thickening. Ordinary paint is one example of a shear-thinning fluid, while oobleck provides one realization of a shear-thickening fluid. Finally, the yield stress quantifies the amount of stress that the fluid may experience before it yields and begins to flow.

This non-Newtonian fluid model was introduced by Winslow Herschel and Ronald Bulkley in 1926.[1][2]

Definition

The constitutive equation of the Herschel-Bulkley model is commonly written as

where is the shear stress, the shear rate, the yield stress, the consistency index, and the flow index. If the Herschel-Bulkley fluid behaves as a rigid (non-deformable) solid, otherwise it behaves as a fluid. For the fluid is shear-thinning, whereas for the fluid is shear-thickening. If and , this model reduces to the Newtonian fluid.

As a generalized Newtonian fluid model, the effective (or apparent) viscosity is given as [3]

The limiting viscosity is chosen such that . A large limiting viscosity means that the fluid will only flow in response to a large applied force. This feature captures the Bingham-type behaviour of the fluid.

In an incompressible flow, the viscous stress tensor is given as a viscosity, multiplied by the rate-of-strain tensor

where the magnitude of the shear rate is given by

- .

The magnitude of the shear rate is an isotropic approximation, and it is coupled with the second invariant of the rate-of-strain tensor

- .

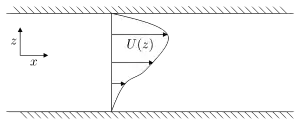

Channel flow

A frequently-encountered situation in experiments is pressure-driven channel flow [4] (see diagram). This situation exhibits an equilibrium in which there is flow only in the horizontal direction (along the pressure-gradient direction), and the pressure gradient and viscous effects are in balance. Then, the Navier-Stokes equations, together with the rheological model, reduce to a single equation:

To solve this equation it is necessary to non-dimensionalize the quantities involved. The channel depth H is chosen as a length scale, the mean velocity V is taken as a velocity scale, and the pressure scale is taken to be . This analysis introduces the non-dimensional pressure gradient

which is negative for flow from left to right, and the Bingham number:

Next, the domain of the solution is broken up into three parts, valid for a negative pressure gradient:

- A region close to the bottom wall where ;

- A region in the fluid core where ;

- A region close to the top wall where ,

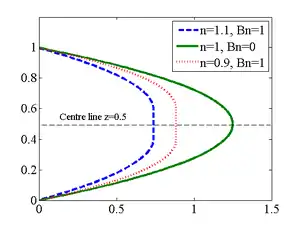

Solving this equation gives the velocity profile:

Here k is a matching constant such that is continuous. The profile respects the no-slip conditions at the channel boundaries,

Using the same continuity arguments, it is shown that , where

Since , for a given pair, there is a critical pressure gradient

Apply any pressure gradient smaller in magnitude than this critical value, and the fluid will not flow; its Bingham nature is thus apparent. Any pressure gradient greater in magnitude than this critical value will result in flow. The flow associated with a shear-thickening fluid is retarded relative to that associated with a shear-thinning fluid.

Pipe flow

For laminar flow Chilton and Stainsby [5] provide the following equation to calculate the pressure drop. The equation requires an iterative solution to extract the pressure drop, as it is present on both sides of the equation.

- For turbulent flow the authors propose a method that requires knowledge of the wall shear stress, but do not provide a method to calculate the wall shear stress. Their procedure is expanded in Hathoot [6]

- All units are SI

- Pressure drop, Pa.

- Pipe length, m

- Pipe diameter, m

- Mean fluid velocity,

- Chilton and Stainsby state that defining the Reynolds number as

allows standard Newtonian friction factor correlations to be used.

The pressure drop can then be calculated, given a suitable friction factor correlation. An iterative procedure is required, as the pressure drop is required to initiate the calculations as well as be the outcome of them.

See also

References

- Herschel, W.H.; Bulkley, R. (1926), "Konsistenzmessungen von Gummi-Benzollösungen", Kolloid Zeitschrift, 39: 291–300, doi:10.1007/BF01432034

- Tang, Hansong S.; Kalyon, Dilhan M. (2004), "Estimation of the parameters of Herschel–Bulkley fluid under wall slip using a combination of capillary and squeeze flow viscometers", Rheologica Acta, 43 (1): 80–88, doi:10.1007/s00397-003-0322-y

- K. C. Sahu, P. Valluri, P. D. M. Spelt, and O. K. Matar (2007) 'Linear instability of pressure-driven channel flow of a Newtonian and a Herschel–Bulkley fluid' Phys. Fluids 19, 122101

- D. J. Acheson 'Elementary Fluid Mechanics' (1990), Oxford, p. 51

- Chilton, RA and R Stainsby, 1998, "Pressure loss equations for laminar and turbulent non-Newtonian pipe flow", Journal of Hydraulic Engineering 124(5) pp. 522 ff.

- Hathoot, HM, 2004, "Minimum-cost design of pipelines transporting non-Newtonian fluids", Alexandrian Engineering Journal, 43(3) 375 - 382