Aluminium oxynitride

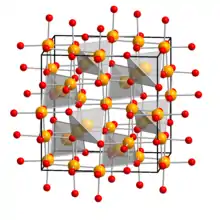

Aluminium oxynitride (marketed under the name ALON by Surmet Corporation[3]) is a ceramic composed of aluminium, oxygen and nitrogen. ALON is optically transparent (≥ 80%) in the near-ultraviolet, visible and midwave-infrared regions of the electromagnetic spectrum. It is four times as hard as fused silica glass, 85% as hard as sapphire, and nearly 115% as hard as magnesium aluminate spinel. Since it has a cubic spinel structure, it can be fabricated to transparent windows, plates, domes, rods, tubes and other forms using conventional ceramic powder processing techniques.

Spinel structure of AlON | |

| Names | |

|---|---|

| Systematic IUPAC name

Aluminium oxynitride | |

| Identifiers | |

| Abbreviations | ALON |

| Properties | |

| (AlN)x·(Al2O3)1−x, 0.30 ≤ x ≤ 0.37 | |

| Appearance | White or transparent solid |

| Density | 3.691–3.696 g/cm3[1] |

| Melting point | ~2150 °C[1] |

| insoluble | |

Refractive index (nD) |

1.79[2] |

| Structure | |

| cubic spinel | |

Except where otherwise noted, data are given for materials in their standard state (at 25 °C [77 °F], 100 kPa). | |

| Infobox references | |

ALON is the hardest polycrystalline transparent ceramic available commercially.[2] Its combination of optical and mechanical properties makes this material a leading candidate for lightweight high-performance transparent armor applications such as bulletproof and blast-resistant windows and for many military infrared optoelectronics.[4] ALON-based armor has been shown to stop multiple armor-piercing projectiles of up to .50 BMG cal.[5]

It is commercially available in sizes as large as 18-by-35-inch (460 mm × 890 mm) monolithic windows.[6]

Properties

- Mechanical

- [2]

- Young's modulus 334 GPa

- Shear modulus 135 GPa

- Poisson ratio 0.24

- Knoop hardness 1800 kg/mm2 (0.2 kg load)

- Fracture toughness 2.0 MPa·m1/2

- Flexural strength 0.38–0.7 GPa

- Compressive strength 2.68 GPa

- Thermal and optical

- [7]

- Specific heat 0.781 J/(g·°C)

- Thermal conductivity 12.3 W/(m·°C)

- Thermal expansion coefficient ~4.7×10−6/°C

- Transparency range 200–5000 nm

ALON also appears to be radiation-resistant and resistant to damage from various acids, bases, and water.[8]

Applications

In addition to being used as a transparent armor material, ALON is used as infrared-optical windows. As such it has applications as a sensor component, speciality IR domes, windows for laser communications, and in some semiconductor-related applications.[9][10]

As a transparent armor material, ALON provides a bulletproof product with far less weight and thickness than traditional bulletproof glass. It has been dubbed transparent aluminium after a fictional Star Trek material.[11] 1.6 inches (41 mm) thick ALON armor is capable of stopping .50 BMG armor-piercing rounds, which can penetrate 3.7 inches (94 mm) of traditional glass laminate.[12]

In 2005, the United States Air Force began testing ALON, "to shield troops".[13]

Manufacture

ALON can be fabricated as windows, plates, domes, rods, tubes and other forms using conventional ceramic powder processing techniques. Its composition can vary slightly: the aluminium content from about 30% to 36%, which has been reported to affect the bulk and shear moduli by only 1–2%.[14] The fabricated greenware is subjected to heat treatment (densification) at elevated temperatures followed by grinding and polishing to transparency. It can withstand temperatures of about 2100 °C in inert atmospheres. The grinding and polishing substantially improves the impact resistance and other mechanical properties of armor.[7]

Patents

- Process for producing polycrystalline cubic aluminum oxynitride JW McCauley U.S. Patent 4,241,000, 1980

- Aluminum oxynitride having improved optical characteristics and method of manufacture TM Hartnett, RL Gentilman U.S. Patent 4,481,300, 1984

- Transparent aluminum oxynitride and method of manufacture RL Gentilman, EA Maguire U.S. Patent 4,520,116, 1985; U.S. Patent 4,720,362, 1988

- Transparent aluminum oxynitride-based ceramic article JP Mathers U.S. Patent 5,231,062, 1993

References

- "ALON Optical Ceramic. Technical data" (PDF). Surmet Corporation. 2003. Archived from the original (PDF) on 2013-06-12. Retrieved 2009-01-09.

- Mohan Ramisetty et al. Transparent Polycrystalline Spinels Protect and Defend, American Ceramic Society Bulletin, vol.92, 2, 20–24 (2013)

- Richard L. Gentilman et al. Transparent aluminum oxynitride and method of manufacture U.S. Patent 4,520,116 Issue date: May 28, 1985

- "Domes & Infrared Optics". Surmet.

- Ramisetty, Mohan; Sastri, Suri A.; Goldman, Lee (Aug 2013). "Transparent Ceramics Find Wide Use in Optics". Photonics Spectra.

- "Surmet Achieves Major Milestone on its ALON Window Scale-up Program". PRWeb. May 28, 2013.

- Joseph M. Wahl et al. Recent Advances in ALON Optical Ceramic, Surmet

- Corbin, N (1989). "Aluminum oxynitride spinel: A review". Journal of the European Ceramic Society. 5 (3): 143–154. doi:10.1016/0955-2219(89)90030-7.

- Lee M. Goldman et al. ALON Optical Ceramic Transparencies for Sensor and Armor Applications, Surmet

- Zhu, Ming; Tung, Chih-Hang; Yeo, Yee-Chia (2006). "Aluminum oxynitride interfacial passivation layer for high-permittivity gate dielectric stack on gallium arsenide". Applied Physics Letters. 89 (20): 202903. doi:10.1063/1.2388246.

- Optically Clear Aluminium Provides Bulletproof Protection, TSS, 3 June 2015, accessed 10 July 2015

- Surmet's ALON Transparent Armor .50 Caliber Test

- Schogol, Jeff (October 30, 2005). "Air Force testing lighter, transparent ALON armor". Stars and Stripes. Retrieved June 25, 2020.

- Graham, Earl K.; Munly, W.C.; McCauley, James W.; Corbin, Norman D. (1988). "Elastic properties of polycrystalline aluminum oxynitride spinel and their dependence on pressure, temperature and composition". Journal of the American Ceramic Society. 71 (10): 807–812. doi:10.1111/j.1151-2916.1988.tb07527.x.

External links

- The Influence of Sintering Additives on the Microstructure and Properties of ALON. Yechezkel Ashuach. Master's Thesis, Technion – Israel Institute of Technology, 2003

- Solubility Limits of La and Y in Aluminum Oxynitride (AlON) at 1870°C Lior Miller and Wayne D. Kaplan. Department of Materials Engineering, Technion, Haifa, Israel, 2006

- Processing of Optically Transparent Aluminum Oxynitride